- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

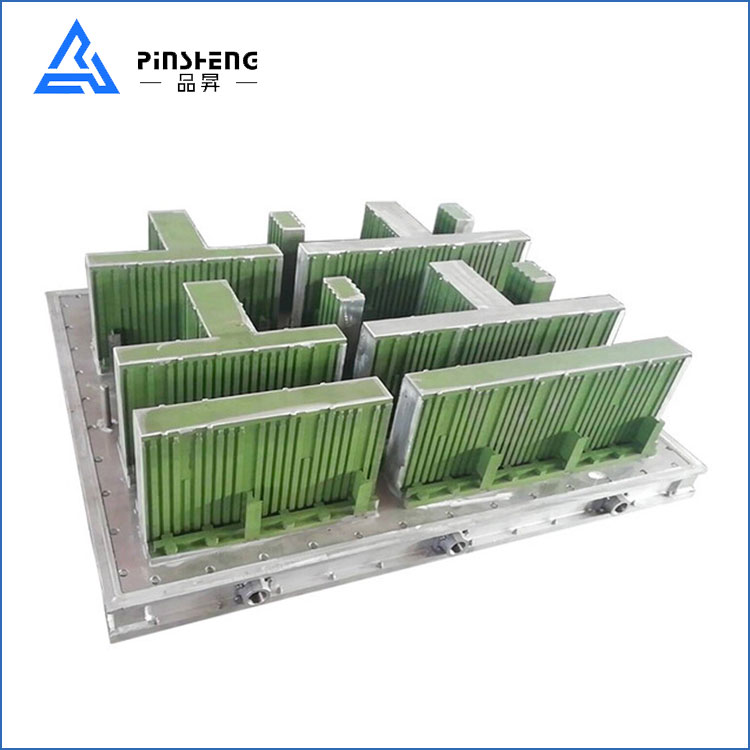

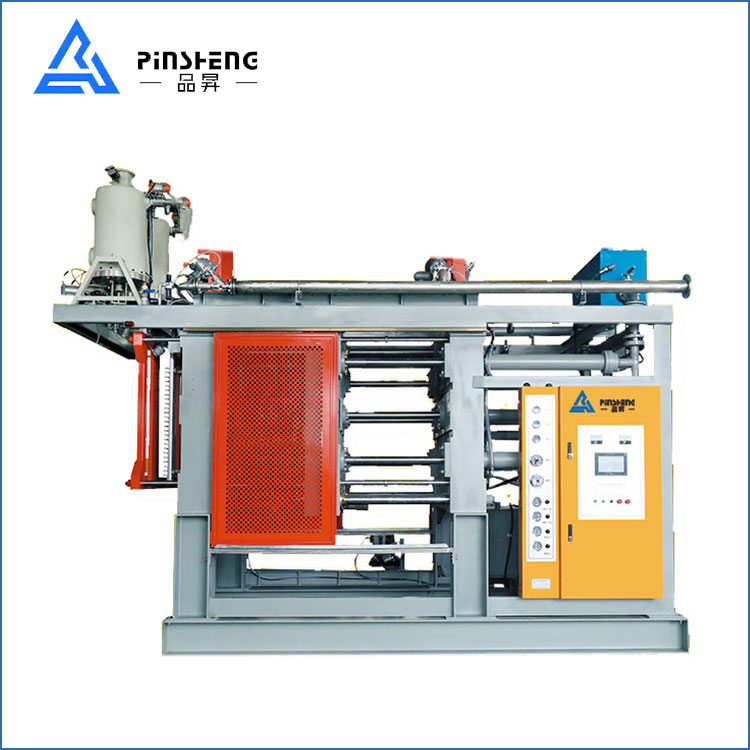

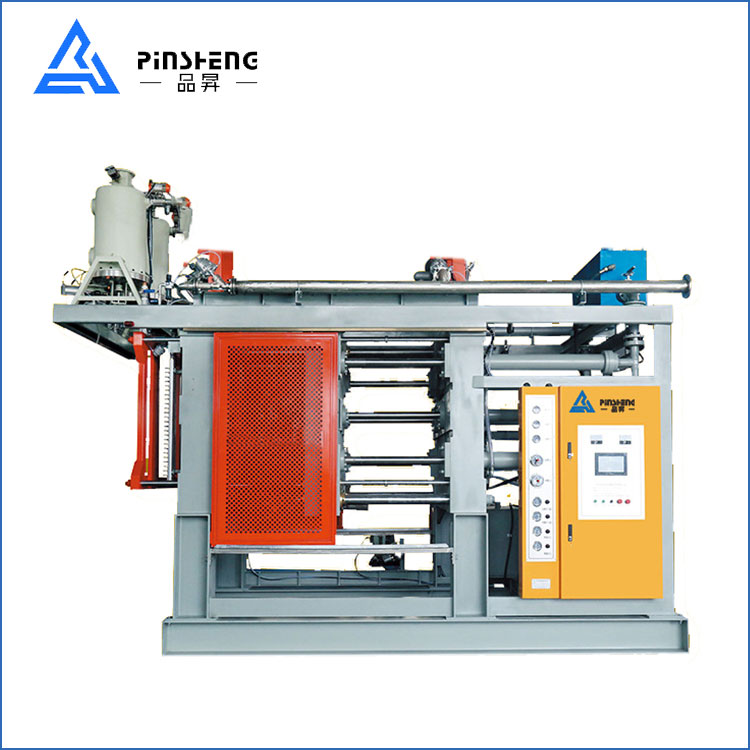

Automatic EPP Moulding Machine

Ningbo PinSheng Machinery Co.,Ltd is committed to developing, designing and producing various of EPS and EPP machines. We strongly recommend our super quality Pinsheng® Automatic EPP Moulding Machine to you. Please don’t hesitate to call us or email us if you have any comments or questions!

Send Inquiry PDF DownLoad

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Wholesale Big Discount Automatic EPP Moulding Machine, Our enterprise warmly welcome close friends from everywhere in the environment to go to, examine and negotiate organization.

Wholesale Big Discount Automatic EPP Moulding Machine, We have been introduced as a one of the growing manufacture supplier and export of our merchandise. We've got a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

Our Pinsheng® Automatic EPP Moulding Machine could produce with all kinds of raw materials, not only EPP raw material but also EPS, EPE,EPO raw material. With Digital pressure control system, steam system, feeding device, the machine can be operated easily with high efficiency.

Model: PSEPP1618

Brand: PinSheng

Product Parameter (Specification)

|

Various application |

Our Automatic EPP Moulding Machine could produce with EPP raw material to be EPP product, but also could use to produce EPP,EPS,EPE,EPO raw material. |

|

Feeding Device |

Our Automatic EPP Moulding Machine has precision material feeding device for faster injection without any dead angle, the density of the material on the muzzle of the feeder will not increase. |

|

3.Precision processing technique |

Our Automatic EPP Moulding Machine adopts precision processing technique, the tolerance between fixed plate and movable plate is within±0.2mm. |

|

4.Hydraulic System |

Our Automatic EPP Moulding Machine is driven by a hydraulic system, with different system guarantee the fast the stable running of the machine |

|

Digital pressure control system |

Our Automatic EPP Moulding Machine adopts digital pressure control system which can adjust the pressure inside the mould more precisely. |

|

Steam System |

Our Automatic EPP Moulding Machine adpots new Steam control system,it can adjust steam pressure and flow rate so as to save steam. |

Product Feature And Application

Pinsheng® Automatic EPP Moulding Machine has a wide range of usage, and one machine has multiple application which can maximize the benefits of the machine.You could produce EPP product for high value Electronic product packaging, tool boxes, toys, building blocks etc.

Deliver,Shipping And Serving

FAQ

1.Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2.Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3.Are you a trading company or a manufacturer?

We are manufacturer.

4.Q:How long is your delivery time of Automatic EPP Moulding Machine?

Normally delivery time is 30~45 days.

5.Q:How many years have your company made this kind of equipment?

More than 10 years.

6.Q:Can I only buy some spare parts from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7.How do you pack the equipment Automatic EPP Moulding Machine?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

8.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

10.Q:How many production lines in your factory?

We have total 10 production line.