- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

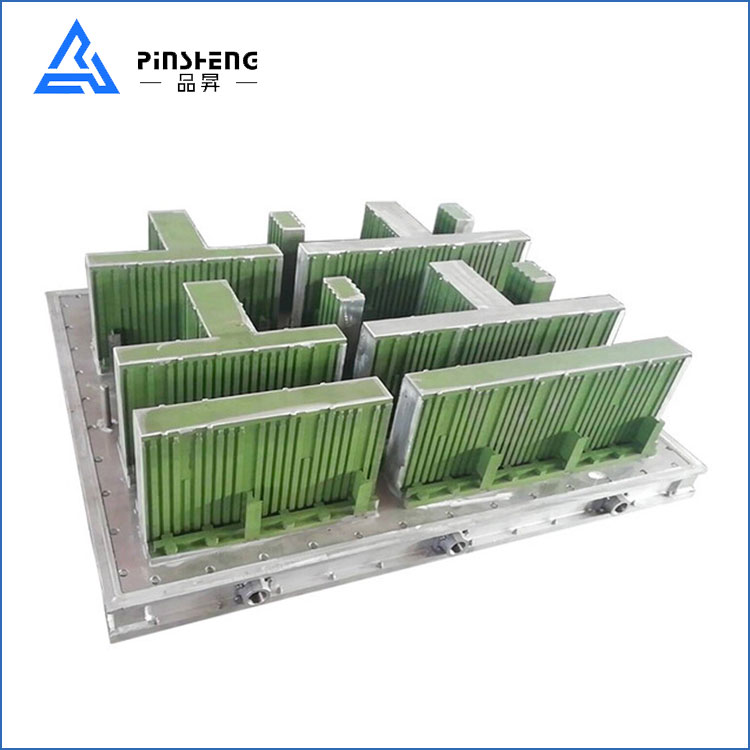

Automatic Vacuum Shape Moulding Machine

Ningbo PinSheng Machinery Manufacturer EPS Pre-expander,Pinsheng® Automatic Vacuum Shape Moulding Machine,EPS Cutting Machines,If you are interested in those machines, we will be your best Choice!

Send Inquiry PDF DownLoad

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Top grade big discount Pinsheng® Automatic Vacuum Shape Moulding Machine, To acquire a consistent, profitable, and constant development by getting a aggressive advantage, and by continuously increasing the value added to our shareholders and our employee.

Top grade big discount Automatic Vacuum Shape Moulding Machine, With a wide range, good quality, reasonable prices and stylish designs, our merchandise are extensively used in public placesand other industries. Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

We are providing qualify Automatic Vacuum Shape Moulding Machine to worldwide clients, our machines has been exported to many countries and received good comments from our clients.

Model:PSSM1412

Brand: PinSheng

Product Parameter (Specification)

|

1.Mechanical structure |

Our automatic Vacuum Shape Moulding Machine apots good quality steel plate,all the formwork is tempered at high temperature and shot peening at high pressure . It has high strength and high surface hardness. All templates are processed by CNC to ensure accuracy |

|

2.Steam System |

Our automatic Vacuum Shape Moulding Machinee provides long range control system reducing valve for stabilizing flow, with control accuracy±0.2 Bar. |

|

3.Electrical control |

Our automatic Vacuum Shape Moulding Machine adopts all worldwide well-known components, such as Taita touch screen,Low-voltage electrical appliances are with the brand Schneider. Through steam pressure,main steam pressure,demoulding,air cooling,and pressurized feeding all adopt remote pressure regulating system,valves open and close according to the set pressure ratio, it is very easy to operate. |

|

4.Hydraulic System |

A digital encoder of the automatic Vacuum Shape Moulding Machine is used to control the stroke distance of mold opening and clamping,it can keep the safety protection function of the mechanical,hydraulic and electrical tripe interlocking so as to meet the safety standard. |

Product Feature And Application

Pinsheng® Automatic Vacuum Shape Moulding Machine is widely used in producing EPS products, we could see those EPS products in all areas of life, such as, vegetable boxes,fruitful boxes,fishing boxes,house hold appliance packaging,etc.

Deliver,Shipping And Serving

FAQ

1.Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2.Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3.Are you a trading company or a manufacturer?

We are manufacturer.

4.Q:How long is your delivery time of Automatic Vacuum Shape Moulding Machine?

Normally delivery time is 30~45 days.

5.Q:How many years have your company made this kind of equipment?

More than 10 years.

6.Q:Can I only buy some spare parts from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7.How do you pack the equipment of Automatic Vacuum Shape Moulding Machine?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

8.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

10.Q:How many production lines in your factory?

We have total 10 production line.