- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

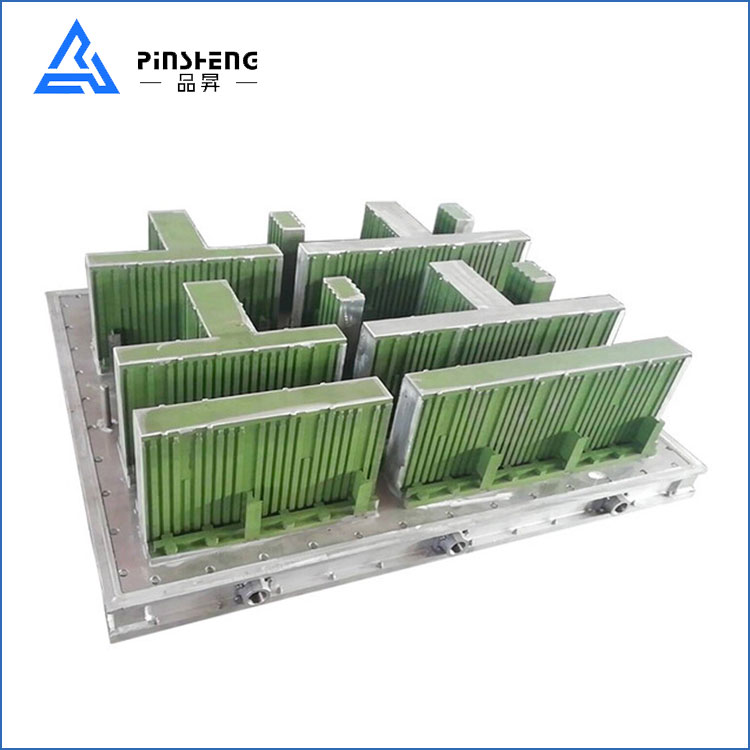

Eps Block Moulding Machine

Ningbo PinSheng Machinery Manufacturer (“PINGSHENG”in short) was established in 2010. With professional R&D team, PINSHENG Machinery has become one of largest and outstanding manufacturer of Pinsheng® EPS Block Moulding Machine, EPS Mould , EPP machine , ETPU machine and other related machines. Our EPS Block Moulding Machine not only has high quality,but also durability strong and high production efficiency. We will be your best Choice!

Send Inquiry PDF DownLoad

Our solutions are greatly recognized and reliable by customers and will fulfill continuously altering financial and social requirements for Top Grade Low Price Eps Block Moulding Machine, We've been prepared to cooperate with company friends from at your home and overseas and produce a wonderful future with each other.

Pinsheng® Top Grade Low Price Eps Block Moulding Machine, Welcome to visit our company and factory, there are various solutions displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to deliver you the best service

Our PSBM200-800VC/AC EPS Block Moulding Machine is a full automatic equipment to produce EPS block, which is efficient and has low energy consumption.

Model:PSBM200-800VC/AC

Brand: PINSHENG

Product Parameter (Specification)

Our Pinsheng® EPS Block Moulding Machine provides all machine process,including filling,expanding,sieving, de-lumping and conveying work automatically.

|

1.Flexible customized size |

The size of EPS Block Moulding Machine can be adjustable . Both in length or width of machine by rotation code to control screw cylinder.By setting the block mold size using the touch screen,the machine will adjust the mould size automatically.The usage method is simple. |

|

2.Machine structure |

The mold of EPS Block Moulding Machine is welded by strong rectangle tube and steel plate which make high strength to keep more safety of the machine. All block mold frames have heat-treatment to release welding stress,so that the frames would not deformed. After heating treatment,all mold frames are processed by sand blasting treatment to keep the rust away,then under coat and finishing coat are greatly improved anticorrosion performance and long life; Adopts three Germany gauges and safety valve for multi-safety protection.The machine will be tested by water pressure and steam(many steps),ensure the machine more safety and stable. |

|

3.Steam system |

The EPS Block Moulding Machine has 3 ball valves ,comparing one big steam valve control system, it can save at least 20% steam,with ISO-standrad butterfly valves ,greatly improve stability and long life. |

|

4.Control system |

The EPS Block Moulding Machine adopts PLC(Mitsubishi) and touch screen(Schneider) for an easy operation; Equipped material level sensor to control the filling.The block cooling is controlled by foam pressure sensor.The whole procedure for filling,heating,cooling will be controlled automatically by PLC. |

Product Feature And Application

The Pinsheng® EPS Block Moulding Machine produce styrofoam for packaing medical,fruit,vetatables and electrical,insulation panels for building.With the good quality,it can be expand 40 times the volume of the original polystyrene beads.

Deliver,Shipping And Serving

FAQ

1.Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2.Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3.Are you a trading company or a manufacturer?

We are manufacturer.

4.Q:How long is your delivery time of Eps Block Moulding Machine?

Normally delivery time is 30~45 days.

5.Q:How many years have your company made this kind of equipment?

More than 10 years.

6.Q:Can I only buy some spare parts of Eps Block Moulding Machine from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7.How do you pack the equipment?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

8.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

10.Q:How many production lines in your factory?

We have total 10 production line.