- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

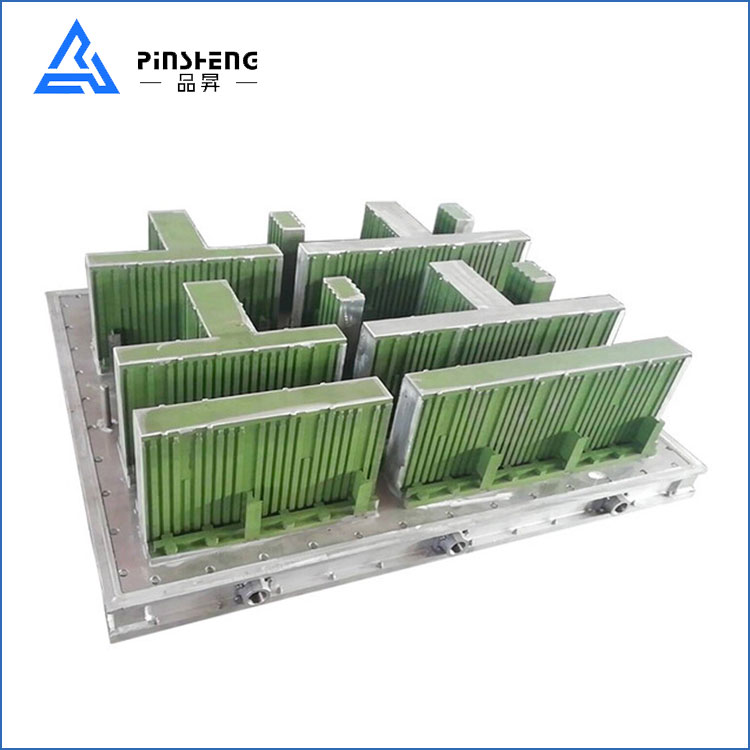

EPS Polystyrene Cutting Machine

Ningbo PinSheng Machinery Manufacturer as one of the leading EPS Machine manufacturers in China, we are also providing Pinsheng® EPS Polystyrene Cutting Machine to worldwide clients, our machines are loved by customers because of their reliability and low energy consumption. If you are interested in EPS Polystyrene Cutting Machine, we will be your best Choice!

Send Inquiry PDF DownLoad

EPS Polystyrene Cutting Machine

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for High Quality reliable supplier of Pinsheng® EPS Polystyrene Cutting Machine, Therefore, we can meet up with different inquiries from different clientele. Be sure to obtain our web page to check much more information and facts from our products.

High Quality reliable supplier of EPS Polystyrene Cutting Machine, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

Model:PSBC3000-6000B

Brand: PINSHENG

|

1. Control System

|

Variable frequency stepless speed regulation. Guide rail drive to smooth cutting of products.Motor speed reducer is integrated. |

|

2. Structure Design

|

Welded by square tube and steel, compact in structure and beautiful in appearance. |

|

3.Processes |

Automatically cut horizontally, vertically, suitable for block cutting. |

|

4. Production Efficiency |

High cutting efficiency and accuracy. Reduce spare time for 3-10min |

Product Parameter (Specification)

|

Item |

Unit |

PSBC-3000B |

PSBC-4000B |

PSBC-6000B |

|

|

Max Cutting Size |

mm |

3000*1250*1250 |

4000*1250*1250 |

6000*1250*1250 |

|

|

Heating Wires Amount |

Cutting Size |

pcs |

60 |

60 |

60 |

|

Vertical |

pcs |

60 |

60 |

60 |

|

|

Port rail |

pcs |

20 |

20 |

20 |

|

|

Working Speed |

m/min |

0~2 |

0~2 |

0~2 |

|

|

Connected Load/Power |

kw |

35 |

35 |

35 |

|

|

Overall Dimension(L*W*H) |

mm |

5800*2300*2600 |

6800*2300*2600 |

8800*2300*2600 |

|

|

Weight |

kg |

2000 |

2500 |

3000 |

|

Product Feature And Application

Pinsheng® EPS Polystyrene Cutting Machine is commonly used for cutting polyfoam , polyform is widely used as packing material for fruit,vetatables,electrical and insulation panels for building. The main frame of EPS Polystyrene Cutting Machine is made of rectangular steel pipe and various special connectors, with stable movement, reasonable structure, stable performance, high precision, advanced technology and easy operation. Using this product can save time, labor and raw materials.

Deliver,Shipping And Serving

FAQ

1.Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2.Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3.Are you a trading company or a manufacturer?

We are manufacturer.

4.Q:How long is your delivery time?

Normally delivery time is 30~45 days.

5.Q:How many years have your company made this kind of equipment?

More than 10 years.

6.Q:Can I only buy some spare parts of EPS Polystyrene Cutting Machine from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7.How do you pack the equipment about EPS Polystyrene Cutting Machine?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

8.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

10.Q:How many production lines in your factory?

We have total 10 production line.