- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

EPS Polystyrene Pre-expander Machine

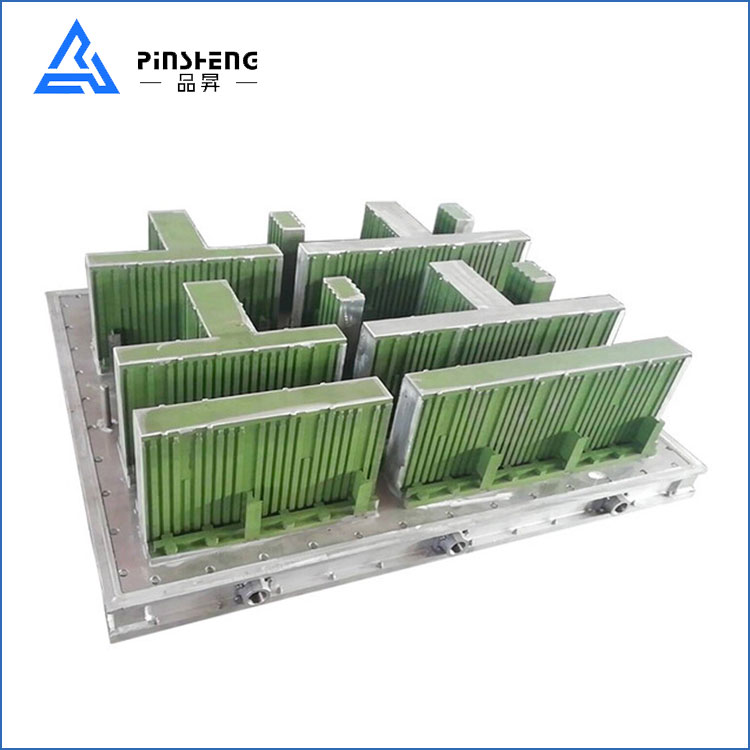

Ningbo PinSheng Machinery Manufacturer who is Pinsheng® professional EPS Polystyrene Pre-expander Machine in China. We not only design,manufacturer all kinds of EPS machine, EPP machine, ETPU machine, but also we produce EPS moulds. With us, you can rest assured for your whole purchases. We ensure you will receive most satisfaction from us.

Send Inquiry PDF DownLoad

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Top grade cheap price EPS Polystyrene Pre-expander Machiner, If you are fascinated in any solutions, you should experience absolutely free to make contact with us for additional details or you should send out us email instantly, we will reply you within just 24 hours and also the best quotation might be provided.

Top grade cheap price EPS Polystyrene Pre-expander Machine, We have been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we have the whole capacity to provide you happy solutions.

Welcome to check below more details of our product instrduction:

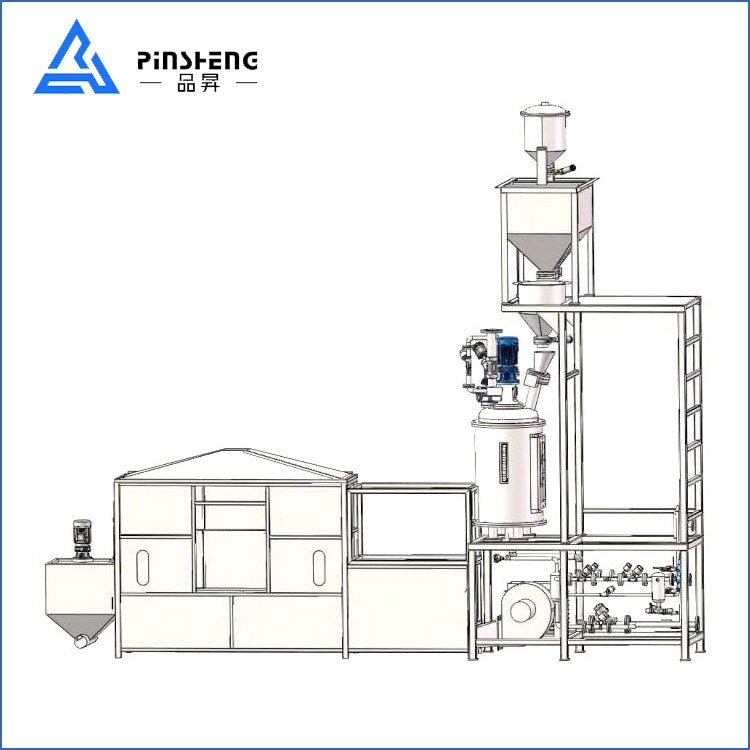

Our Pinsheng® EPS Polystyrene Pre-expander Machine Can meet all your basic demands: Stable feeding speed, high production efficiency,stable density, good foam quality, low steam consumption.

Model:PSPEB-N70/150

Brand: PinSheng

Product Parameter (Specification)

The following is the introduction of our EPS Polystyrene Pre-expander Machine which includes dryer bed,screw conveyer, filling,sieving devices., our Batch EPS pre-expander could Minimize operating errors due to its clear operation interface.

|

1.Steam System |

The EPS Polystyrene Pre-expander Machine has steam system reducer and angel valve to control system which allows the machine to operate correctly and produce high quality EPS foam beads. |

|

2.Filling System |

Thanks to the electronic weighing system,after setting the weight on the touch screen, the EPS Polystyrene Pre-expander Machine can realize automatic feeding. |

|

3.Material Level Control |

Use photo sensor to control the expansion level. |

|

4.Electric Control |

With PLC and Touch Screen,the whole process of EPS Polystyrene Pre-expander Machine could be realized automatically. |

Product Feature And Application

Pinsheng® EPS Polystyrene Pre-expander Machine is such a machine which expand EPS raw material beads to be EPS foam beads and then with EPS mould machine, we could produce all kinds of EPS products like fishing boxes, ice cream boxes,sandwich panels.

Deliver,Shipping And Serving

FAQ

1.Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2.Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3.Are you a trading company or a manufacturer?

We are manufacturer.

4.Q:How long is your delivery time?

Normally delivery time is 30~45 days.

5.Q:How many years have your company made this kind of equipment?

More than 10 years.

6.Q:Can I only buy some spare parts of EPS Polystyrene Pre-expander Machine from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7.How do you pack the equipment of EPS Polystyrene Pre-expander Machine?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

8.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

10.Q:How many production lines in your factory?

We have total 10 production line.