- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

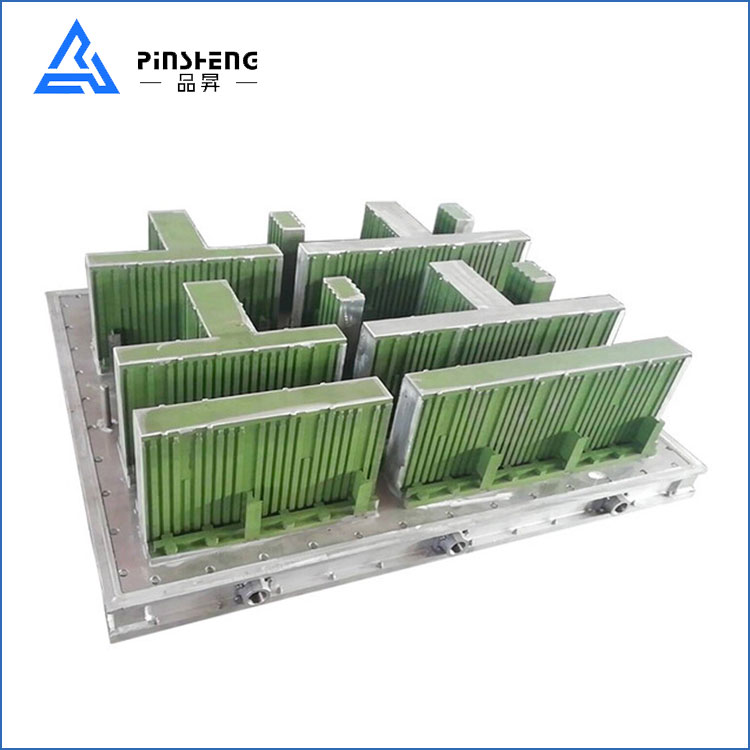

ETPU Shape Moulding Machine

Products and services are the life of an enterprise. Ningbo PinSheng Machinery Manufacturer has always attached great importance to product quality and after-sales tracking services. We strive to provide customers with satisfactory high quality Etpu Shape Moulding Machine and services through our own efforts. If you have questions about product use and functions, you can contact us 24 hours a day. The following is the introduction of Etpu Shape Moulding Machine, hoping to help you better understand Etpu Shape Moulding Machine. Welcome new and old customers to continue to cooperate with us to create a better future!

Send Inquiry

The Pinsheng® ETPU Shape Moulding Machine Makes High Quality ETPU

As a professional ETPU Shape Moulding Machin manufacture, Pinsheng® ETPU Shape Moulding Machin can produce high performance ETPU.By changing the structure of the TPU recombination of high rebound foam particles of the new TPU foam material, called ETPU popcorn material. ETPU is a new polymer material composed of numerous elastic and lightweight TPU foam balls. It has the characteristics of environmental protection, ultra-light density, easy deformation, high wear resistance, temperature change resistance and yellowing resistance.

ETPU is an elastomeric material consisting of amorphous and rigid molecular chains that do not contain any flexible chain segments in its molecular structure. Therefore, ETPU material not only has the strength and dimensional stability of amorphous resin, but also has the chemical resistance, fatigue resistance and wear resistance of crystalline resin.

ETPU Moulding Machine Introduction

Model:PSEETPU

Brand: PinSheng

High Quality ETPU Shape Moulding Machin Feature And Application

Pinsheng® ETPU Shape Moulding Machin is made from the best materials and accessories on the market and will provide you with premium ETPU molding products.

1.1 High-precision seam technology, high-strength square tube welded by tempering prevent form deformation

1.2 High frequency impulse proportional distribution feed system.

1.3 The polystyrene moulding machine sets independent air chamber of separate control, flexible for production scheduling.

1.4 Application of digital proportional control technology offers more accurate control and easier operation, can also make the polystyrene moulding machine has higher production efficiency

1.5 Mitsubishi PLC control system make the ETPU automatic moulding machine easy control.

Product Parameter (Specification)

|

N0. |

Item |

Parameter |

|

1 |

Molding Specifications |

1002X4 1002X3 1002X2 |

|

2 |

Precision mold accuracy |

0.1mm |

|

3 |

Steam Pressure Control |

0.01kg |

|

4 |

Ejection Flow control |

0.01kg |

|

5 |

Hydraulic Control System |

Double mercury,single oil cylinder |

|

6 |

Hydraulic Clamping Capacity |

40T |

|

7 |

Travel speed |

250mm/s |

|

8 |

Control System |

Mitsubishi PLC |

|

9 |

HMI |

WEINVLEW |

|

10 |

Guide Post |

Φ75mmX4X4 |

|

11 |

Steam Inlet |

DN80 |

|

12 |

Water Inlet |

DN80 |

|

13 |

Perssure Air Inlet |

DN80 |

|

14 |

Drainge Outlet |

DN150 |

FAQ

1. Q:Can I only buy some spare parts from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

2.How do you pack the equipment?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

3.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

4.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

5.Q:How many production lines in your factory?

We have total 10 production line.