- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

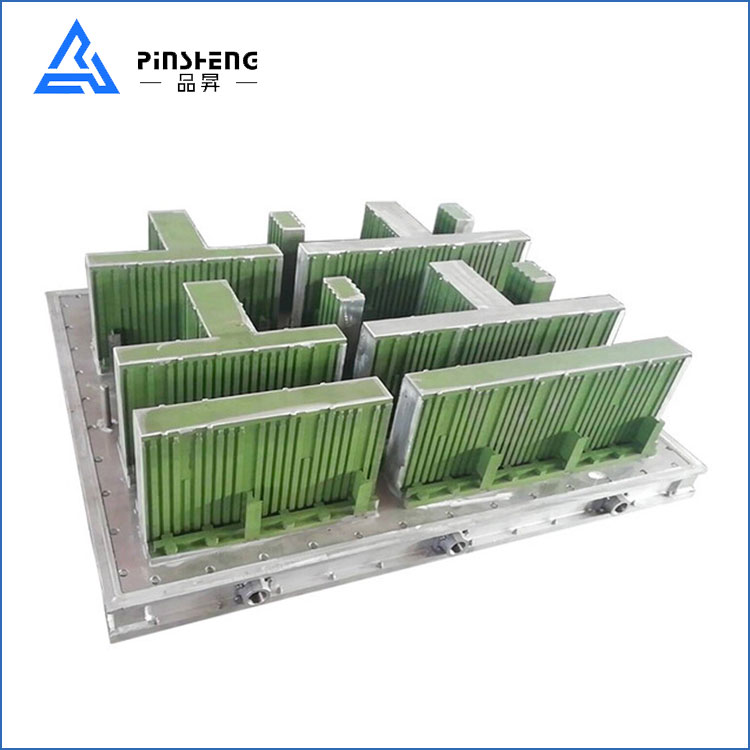

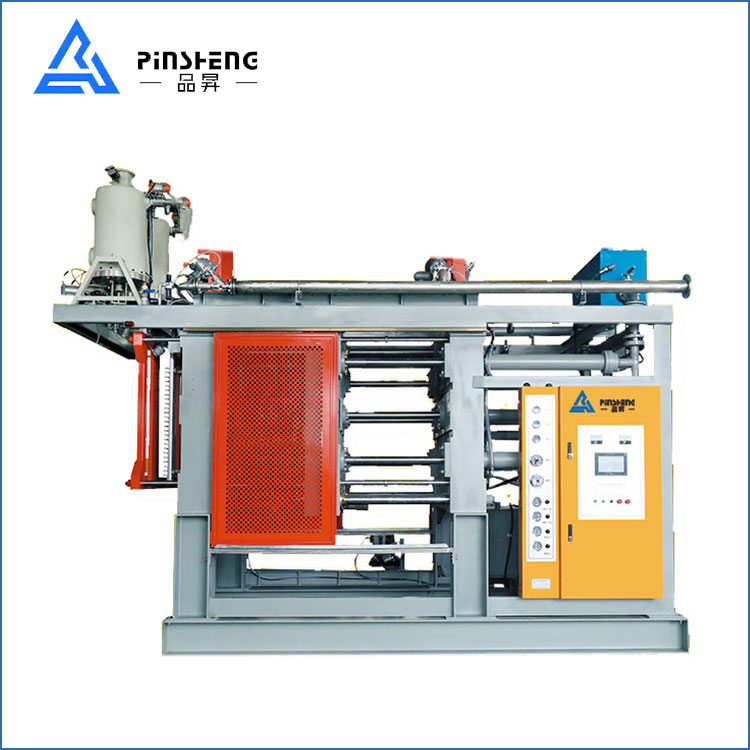

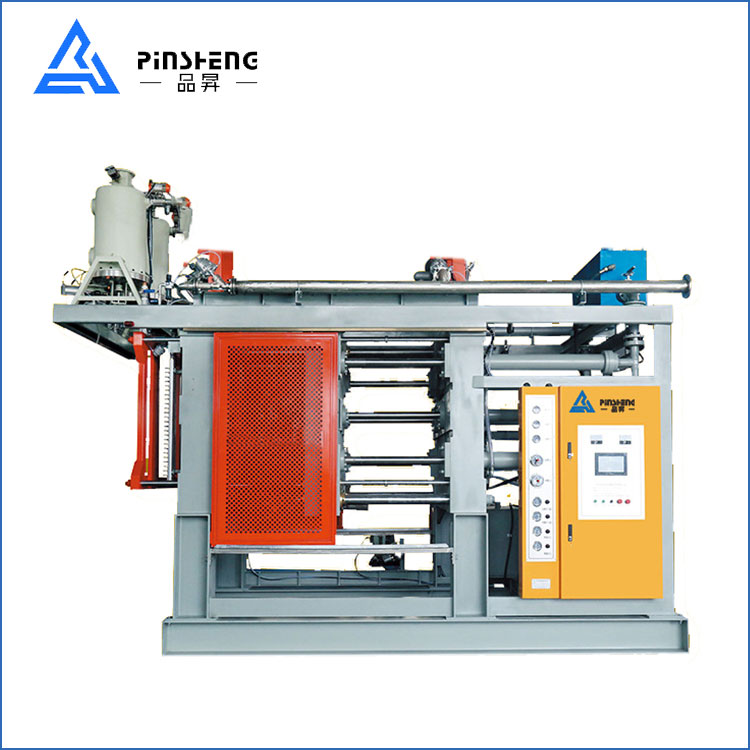

EPP Foam Shape Injection Molding Machine

Ningbo PinSheng Machinery Manufacturer specializes in manufacturing EPP, EPS, ETPU machine and high quality EPP Foam Shape Injection Molding Machine for nearly 10 years with integrating independent R&D, production, sales and service. Our Factory is located in China, and close to important ports such as Shanghai and Ningbo, the geographical position is superior, transportation and shipping are very convenient. Our EPP Foam Shape Injection Molding Machine have a good quality and price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.

Send Inquiry

The Pinsheng® high quality EPP Foam Shape Injection Molding Machine

The following is the introduction of high quality EPP Foam Shape Injection Molding Machine, hoping to help you better understand EPP Foam Shape Injection Molding Machine. Welcome new and old customers to continue to cooperate with us to create a better future!

With the rapid development of China economy, the scale of construction in China will increase rapidly in the coming years, and there is an increasing demand for insulation materials for buildings. EPP material has excellent performance, which can not only maintain the thermal insulation performance of energy-saving building roof and exterior wall, but also prevent the leakage of insulation layer. Some architects say that the EPP material has good insulation properties outside the exterior walls, high strength. Therefore, the building insulation market supports the demand of high quality EPP Foam Shape Injection Molding Machine.

Model:PSEPP80-130

Brand: PinSheng

Product Introduction

high quality EPP Foam Shape Injection Molding Machine Main features

1.1 Sustained impact resistance: When sustained impact, absorb energy and immediately restore to the original state, without deformation.

1.2 Expanded polypropylene has strong molecular stability, oil resistance, water resistance and chemical resistance: the product can be exposed to water for a long time and is not affected by chemical agents. Compared with similar materials, its products have better flexibility and are not easy to damage.

1.3 Floatability: The closed-cell structure makes the product have excellent floatability for a long time. Even if placed in salt water, it will not weaken its floatability at all.

1.4 Anti-elasticity and anti-flexibility: with "memory" ability, can be quickly restored after bending deformation.

1.5 Acoustic characteristics: sound insulation efficiency is high, adding other materials can be made into good noise reduction products.

1.6 Recyclable features :EPP products are "environmental protection products", non-toxic and pollution-free, easy to decompose and recycle.

Product Parameter (Specification)

high quality EPP Foam Shape Injection Molding Machine Feature And Application

Continuous Pre-expander produces all kinds of EPS EPP product.EPP has a wide range of applications. IT products, electronic communication equipment, liquid crystal display, plasma color TV, precision electronic components, precision instruments and meters began to use a large number of EPPs as packaging materials. Another particularly important application field is a large number of applications in the automobile industry: car bumper, car side shockproof core, car door shockproof core, advanced safety car seats, children's safety seats, toolbox, trunk, armrest, bottom pad, visor, dashboard, etc.

FAQ

1.Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2.Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3.Are you a trading company or a manufacturer?

We are manufacturer.

4.Q:How long is your delivery time?

Normally delivery time is 30~45 days.

5.Q:How many years have your company made this kind of equipment?

More than 10 years.

6.Q:Can I only buy some spare parts from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7.How do you pack the equipment?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

8.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

10.Q:How many production lines in your factory?

We have total 10 production line.