- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

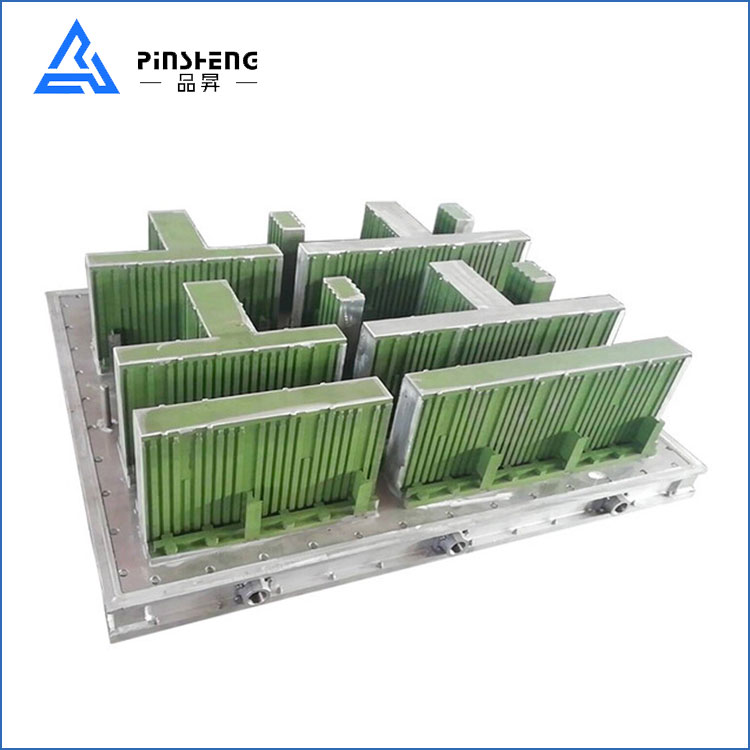

ETPU Foam Molding Unit

Ningbo Pinsheng Machinery Co., Ltd. is an experienced manufacturer of ETPU foam molding unit. To provide reliable and efficient solutions for global foam product manufacturers. Customers in more than 30 countries around the world. We provide exceptional service and support to our customers and have a team of dedicated professionals who can help them meet their specific needs. In short, Pinsheng ® is a leading manufacturer of ETPU molding machines, providing reliable and efficient solutions to foam product manufacturers worldwide. If you need ETPU molding machine or ETPU related materials, please contact us in time, we will reply you the first time!

Send Inquiry

The Pinsheng® ETPU Foam Molding Unit

The ETPU foam system produced by Ningbo Pinsheng Machinery Co., Ltd. can be used for shoe, automobile, sports and leisure industries. For example, manufacturers of popcorn sports insoles using ETPU foam can enhance the shock absorption, flexibility and wear resistance of shoes, providing their customers with comfortable, durable and long-lasting products. Pinson ® ETPU foam system is made of the finest materials and molding equipment available on the market. The automated molding equipment makes the ETPU Foam System easy to use and operator friendly. Pinsheng ® to provide you with excellent performance ETPU molding machines, welcome to convey your needs to us and buy the machine you need.

ETPU Foam Molding Unit Introduction

Model:PSEETPU

Brand: PinSheng

The Pinsheng® ETPU foam molding unit for popcorn soles is made form the best materials and accessories on the market. Automatic equipment make the method of operation of ETPU foam molding unit simple. The ETPU foam molding unit is high-performance and will provide you high-class ETPU moulding product.

1.1 The polystyrene moulding machine sets independent air chamber of separate control, flexible for production scheduling.

1.2 Application of digital proportional control technology offers more accurate control and easier operation, can also make the polystyrene moulding machine has higher production efficiency

1.3 High frequency impulse proportional distribution feed system.

1.4 Mitsubishi PLC control system make the ETPU automatic moulding machine easy control.

1.5 High-precision seam technology, high-strength square tube welded by tempering prevent form deformation

Product Parameter (Specification)

|

N0. |

Item |

Parameter |

|

1 |

Molding Specifications |

1002X4 1002X3 1002X2 |

|

2 |

Precision mold accuracy |

0.1mm |

|

3 |

Steam Pressure Control |

0.01kg |

|

4 |

Ejection Flow control |

0.01kg |

|

5 |

Hydraulic Control System |

Double mercury,single oil cylinder |

|

6 |

Hydraulic Clamping Capacity |

40T |

|

7 |

Travel speed |

250mm/s |

|

8 |

Control System |

Mitsubishi PLC |

|

9 |

HMI |

WEINVLEW |

|

10 |

Guide Post |

Φ75mmX4X4 |

|

11 |

Steam Inlet |

DN80 |

|

12 |

Water Inlet |

DN80 |

|

13 |

Perssure Air Inlet |

DN80 |

|

14 |

Drainge Outlet |

DN150 |

FAQ

Q:How many years have your company made this kind of equipment?

More than 10 years.

Q:Can I only buy some spare parts from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

Q:How do you pack the equipment?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

We will provide very detailed installation manuals and videos, and the service until you are satisfied

Q:Are you a trading company or a manufacturer?

We are manufacturer.